Aisin AW TF-81SC: A vigorous veteran

Automatic transmission repair expert

The Japanese company Aisin AW created the TF-80SC almost 15 years ago. The unit is intended for front-wheel and all-wheel drive vehicles with an east-west engine mounting. That is why the transmission is quite space effective – its length is a mere 358 mm. In order to have six gears in such limited space, the designers used the Lepelletier-type gearset (see “AKPPro” #3, p. 18). This transmission designed for the transfer of quite a high torque is installed in models of various vehicle classes – С (OpelAstra, Chevrolet Cruze), Е (Volvo S80), as well as CUVs (Mazda CX-7 and CX-9) and minivans, or multi-purpose vehicles (Renault Espace). These transmissions work with engines from 1.9 to 4.4 L, the torque limitation being 450 Nm.

Some manufacturers used a special labelling for this transmission – AF21 (TF-81SC) for Ford and AF40-6 (TF-80SC) for Ford and GM, AM6 for Peugeot and Citroen, AW6A-EL for Mazda. They have slight diff

erences in their design – namely, in the valve bodies (besides, there may be different varieties for the same vehicle model), and the TF-81SC differs from the TF-80SC in the number of frictions.

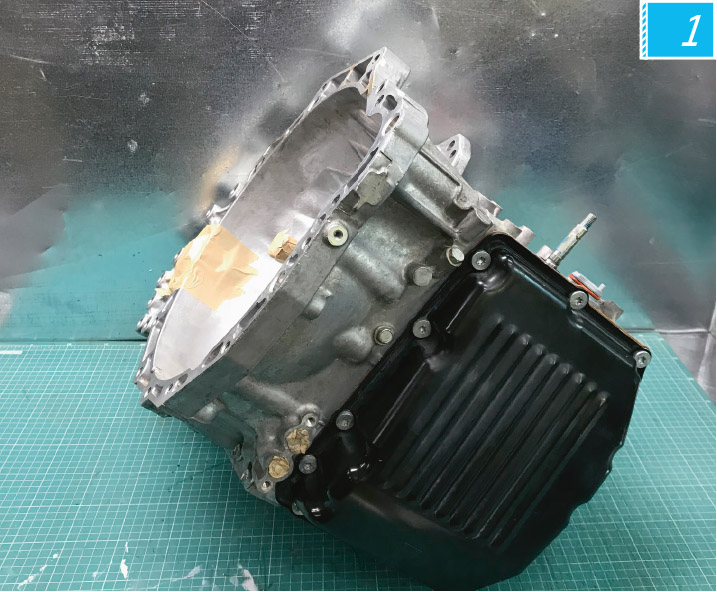

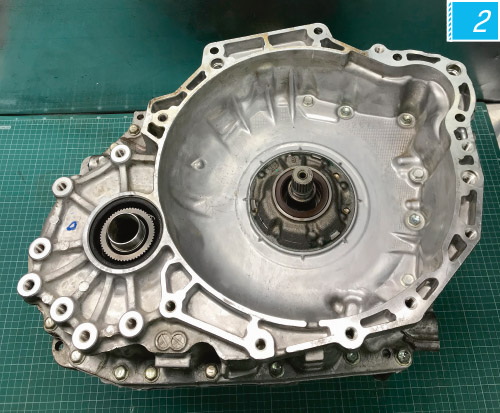

In 2010, this transmission was slightly modernized. As a result, some of the “congenital” disorders and failures have been eliminated. We are going to have a look at the transmission of Land Rover Freelander 2 (Fig. 1, 2) with a 2.2 L diesel.

Torque converter TF-81SC

The main source of trouble for a TF-81SC owner is usually the torque converter and the valve body. And in most cases the problem is associated with transmission overheat and infrequent oil change.

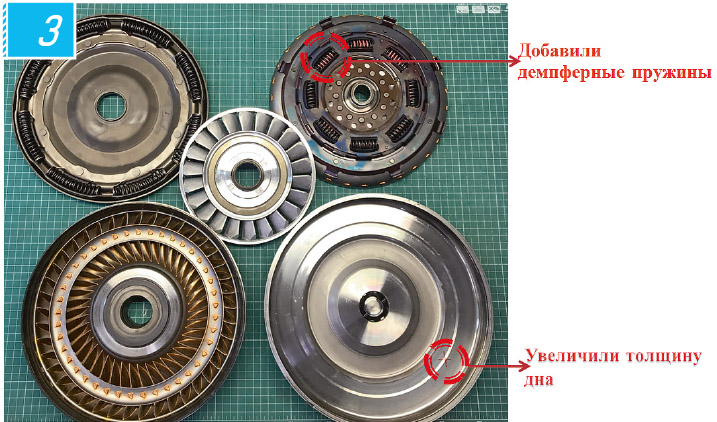

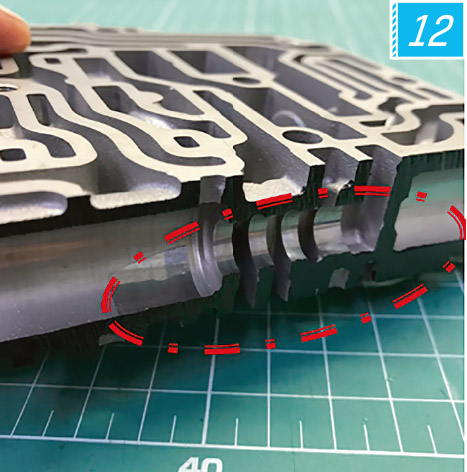

As a result of the modernization, the torque converter got equipped with additional shock absorbing springs. Also, the bottom surface of its back cover became thicker on the transmission lock-up piston side (Fig. 9). The strengthening of the surface reduces the strain and alteration of the form of the bottom, which was often the case in the first generation of torque converters. Due to such deformity, the friction material got worn unevenly (Fig. 12). And although in modern transmissions this problem has been eliminated, the friction plate still wears intensively – yet, now the wear is uniform. It still has to be replaced, but less frequently than before.

Sometimes the one-way clutch bearing falls apart (Fig. 13). This does not happen often, and the cause of that is overload. It mostly occurs in transmissions working with diesel engines – such engines tend to develop a high torque even at low rpm. The original bearing is not supplied separately, it can only be taken off from a used torque converter. We install new Sonnax bearings, and these components are also produced by other manufacturers.

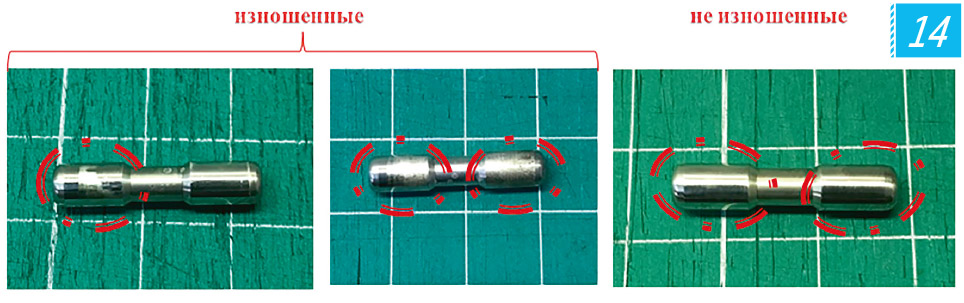

I have often encountered transmissions where the oil pump bushing spun (or slipped) (Fig. 14 (IMG_4281), 15 (IMG_4282)), because it was stuck to the torque converter front cover hub due to overheating. It resulted in oil leakage and, if the trouble was not corrected, the whole transmission could gо out of order. At low oil level, the pump was drawing in air making characteristic buzzing sounds. And, naturally, the leak is clearly seen during inspection.

The pump can be restored only on condition that the rotor is intact: it is necessary to thoroughly inspect it because it is the first component affected by oil starvation. If the rotor has signs of breakdown or severe wear, the pump assembly is to be replaced – not necessarily with a new one, a used one will do too if it is in mint condition.

Oil and filter TF-81SC

In manuals for vehicles equipped with the TF-81SC and TF-80SC it can be specified that oil in this transmission is intended for the entire duration of its lifetime. However, under our conditions, an oil change at least once a year or two will considerably reduce the chance of failures. The fact is that this gearbox is very sensitive to the fluid characteristics, therefore I recommend to change oil every 20–30 thousand km.

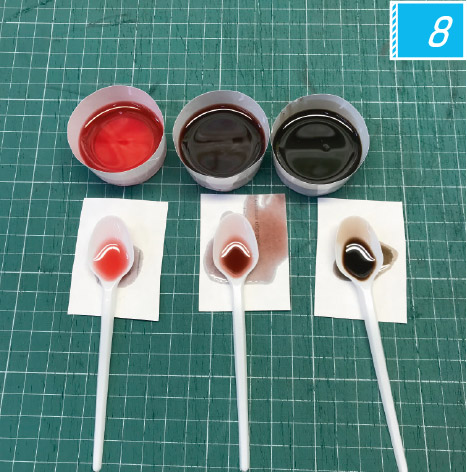

The oil gets dirty, and it is clearly seen by its color: in Fig. 16 you can see fresh oil, used – but still usable oil, and waste oil which should have been changed long ago.

A transmission with fresh fluid is less prone to overheating – new oil carries away heat better. Of course, in the TCM there is a protection mode which, when reaching a temperature of 129 C, in most cases blocks the torque converter, but it is better not to bring the transmission to a state for emergency modes.

The frequency of oil changes depends on the operating mode and working conditions. In case of regular commutes in a big city with all its horrendous traffic, or when driving aggressively (with slam acceleration and abrupt braking), it is possible to turn the fluid into unusable dregs in 10 thousand km. On the other hand, when making long trips without harsh speeding up, the oil will serve several times longer.

For oil change, the original transmission fluids Aisin AW – AW-1 or Toyota WS are recommended. Also, feel free to use their analogs – for instance, the semi-synthetic oils ATF Ravenol T-IV and Mobil (or Esso, since they are brands of the same company) 3309.

The oil filter (Fig. 6, 24, at your discretion) is arranged in such a way that to replace it you need to dismantle the transmission and partially disassemble it. Timely oil change helps to keep the filter relatively clean and makes it possible to buy some time before the filter change becomes inevitable.

Valve body TF-81SC

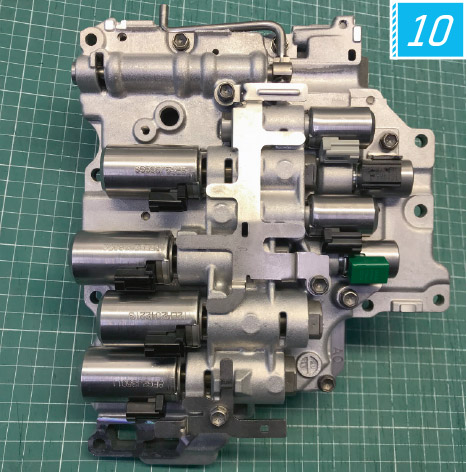

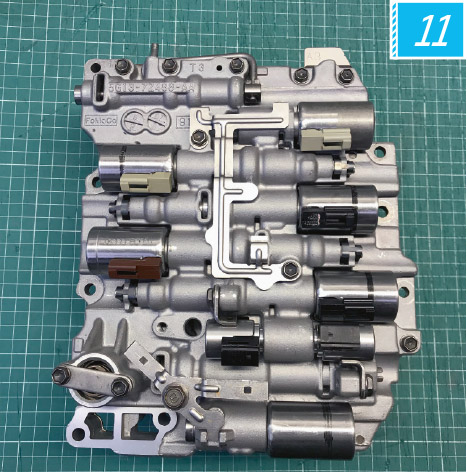

After being modernized, the valve body changed completely – you can see the difference, as they say, with the naked eye (Fig. 4 and 5). However, it has to be borne in mind that valve bodies for different vehicle models are different too.

In transmissions designed before 2010 there were a lot of problems connected with components wear. After their modernization, many of the problems were solved, not least because of the reduced number of mechanical valves. Yet, the engineers did not manage to tackle all the problems. In the middle part of the valve body where the torque converter lock-up valve is located (Fig. 17), excessive wear of the valve body case, as well as the lock-up valve itself is possible. There can be various causes of that: dirty oil (or the wrong choice of the oil type, since the valves are designed for the specific characteristics of the transmission fluid), as well as overloading. The wear becomes obvious in motion, when the locking-up of the torque converter does not occur, so the acceleration becomes worse and the fuel consumption goes up.

Sometimes, when pulling off after releasing the brake pedal, the vehicle is not moving for a second or two, and then abruptly darts off. In some models (e.g., Opel Astra), such behaviour can be caused by the “induced Neutral” mode, which is normal. Yet, in models where this function is not provided for, e.g. in Volvo and Land Rover, this indicates a valve body failure. The root of the problem can be the electromagnetic valve or the plungers. Sometimes this is caused by a failure of the transmission ECU software.

Incidentally, in some not infrequent cases a reflashing (or update) of the TCM eliminates some of the problems.

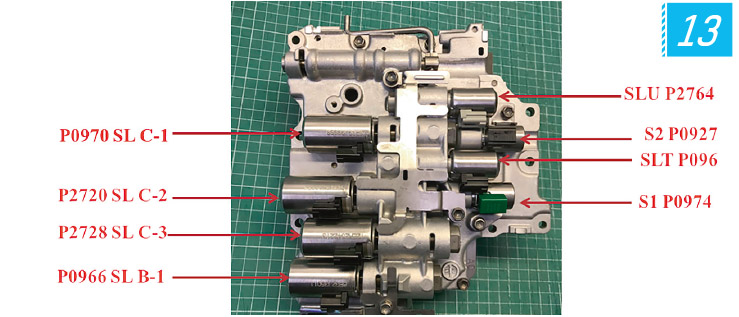

Faulty solenoids can easily be identified by means of diagnostic trouble codes (Fig. 18). In a valve body, two valve types are used: the first one raises the pressure at increased current intensity, the other one does the exact opposite. However, the wear of the working surfaces deteriorates the operability of both.

Fig. 19 – Pressure-regulating valve with increasing mode; pressure-regulating valve with decreasing mode (in the same place)

Just like the lock-up valve, the pressure regulators are also prone to wear (Fig. 20), which leads to a change in their characteristics. Eventually, the driver feels a somewhat slurred and indistinct or, on the contrary, too sharp and violent engagement of some gears. When applying to a car-service centre, customers complain of: jerks and slipping when shifting gears during slam acceleration or braking. The jerks can be observed in a non-faulty transmission too, if it hasn’t warmed up yet, but there aren’t supposed to be any jerks in a warmed-up transmission even if you stomp on the accelerator really hard.

A sure sign of valve problems is the increase in the jerks frequency and intensity at steeply increasing rpm, with no jerks at smooth acceleration.

If you can feel the jerks constantly and at any speed, the cause can be in the mechanical part – the wear or damage of the rubber, teflon, and rubber-metal seals or pistons.

This defect can also be associated with the modulation valve in the valve body. In the new version of the TF-81SC, there is only one modulation valve; there used to be two in the previous versions: one was activated at a pressure decline, the other – at a pressure increase. Yet, the main cause is the electromagnetic valves which are directly responsible for the engagement of a certain gear.

To solve the valve body problem it is not enough to wash it and clean it, as many believe (and do). The valve body cleaning is capable of eliminating some of the symptoms for a short period of time, but it won’t solve the problem. And eventually the client will return to you – or will turn to another car service centre. It is necessary to adopt a professional approach to diagnostics, as well as use high-quality spare parts and sometimes very costly equipment. I strongly recommend using original equipment from renowned manufacturers and special software for diagnostics and adaptation procedures after repair. When making your choice, please, make sure that the software version you are purchasing supports adaptation. Full-fledged adaptation requires several hours of driving in various regimes and modes.

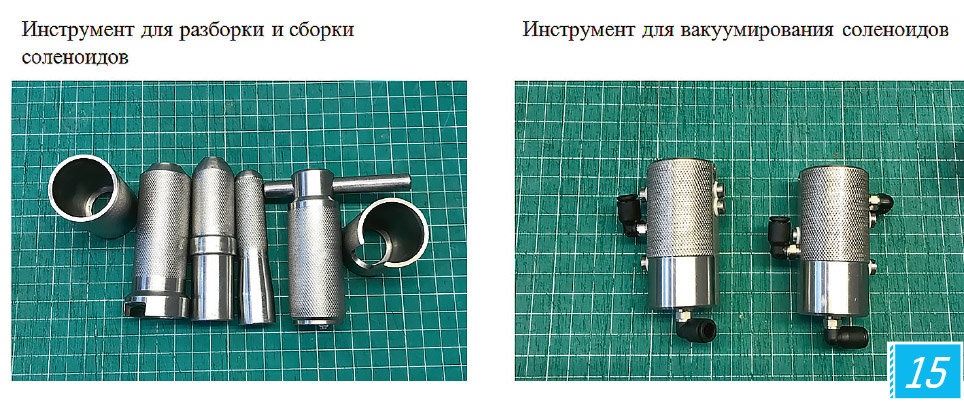

OE solenoids are not sold separately so you will have to replace the valve body assembly. Sometimes it is cheaper to replace the valves alone, although it may require the use of special tools and devices (Fig. 21).

There are several options: if all the valves are worn, as is often the case after aggressive driving, the total cost of the repair (including parts, special tools and work) can exceed the cost of replacing the valve body assembly. When accelerating smoothly, only three or four valves usually wear.

As a rule, clients say that they take special care of their car and the failure is a minor one. But many of them are far from being sincere at this moment. It is important to warn the clients in advance that the cost of the repair is only finally determined after the transmission disassembly.

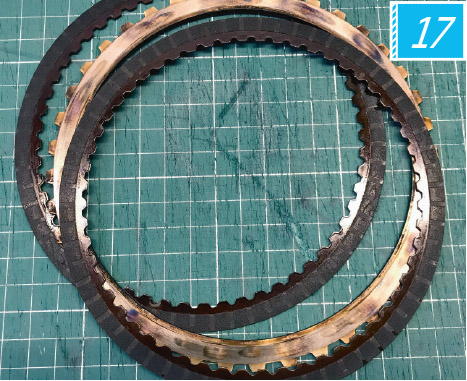

Another likely cause of problems is the penetration of the antifreeze mixture from the engine cooling system inside the transmission. This results in the exfoliation and peeling of the friction material (Fig. 22). In an old transmission, during the years of its operation, the material can wear simply due to its age, but the penetration of the antifreeze into the transmission speeds up the process manyfold.

Sometimes, clutches burn too (Fig. 23). The usually causes are the low oil level due to leaks or improper operation.

Mechanical unit TF-81SC

The planetary gear sets themselves in these transmissions hardly ever go out of order. It can only happen at severe overloads.

However, in transmissions installed in such CUVs as Mazda CX-7 and CX-9, failures often occur in the connection of the transfer case to the differential. It seems that in the course of time, the lubrication applied by the manufacturer wears off, which leads to a breakdown of the spline connection. The ways of dealing with the problem include the replacement of the differential assembly, or its rebuilding – overlay metal welding, heat treatment and cutting of new splines.

Operating instructions

Like almost all automatic transmissions, the unit Aisin AW does not like burnouts and wheel spins, as well as aggressive driving for a prolonged period of time. I have mentioned before that the TF-81SC and TF-80SC are susceptible to overheating. Extreme operation modes first lead to changes in transmission characteristics – in response to the TCM commands, - and then the vehicle electronic unit can no longer limit the rpm. Yet, one should not count on the electronic “brain” for saving the transmission, because many determined drivers can overcome this type of protection and none the less damage the transmission.

Even the “heaviest” versions of this transmission are intended for the transfer of torque of up to 440–450 Nm. So, if the car owner increases the engine capacity (e.g., by chip-tuning) and the torque exceeds the maximum threshold, the service life of the transmission will become significantly shorter.

The transmission is sensitive to high temperatures as well. To my clients I recommend, in wintertime, first slightly warm up the engine with the selector lever in the P position, and then shift it into D and hold the car on brake for about a minute or a bit more. Only then you should start moving very slowly and smoothly for the first 15 or 20 km, until the transmission gets warmed-up.

Caring attitude towards the transmission can prolong its service life and reduce the chances of failures.

Author’s note:

It is always important to remember that in a modern vehicle all units are interconnected with each other. Let me give you an example. We once had a client with a long-used Volvo XC90 – the mileage was over 200 thousand km. His complaint was that when exceeding the speed of 80 km/h, a transmission failure indicator went on. The scanner reported a torque converter lock-up solenoid failure. We rebuilt the valve body, but nothing changed! After a short ride, the transmission failure message still appeared. The client insisted that the failure had appeared not so long before and there were no other problems with the car.

It is always important to remember that in a modern vehicle all units are interconnected with each other. Let me give you an example. We once had a client with a long-used Volvo XC90 – the mileage was over 200 thousand km. His complaint was that when exceeding the speed of 80 km/h, a transmission failure indicator went on. The scanner reported a torque converter lock-up solenoid failure. We rebuilt the valve body, but nothing changed! After a short ride, the transmission failure message still appeared. The client insisted that the failure had appeared not so long before and there were no other problems with the car.

However, after a thorough examination it turned out that the wheel position sensor was down. The car owner said that he had been driving like that for a long time, because this sensor is intended for the correct operation of the stabilization systems, which he, being an experienced driver, does not need. The replacement of the sensor was pretty expensive, about 15 000 rubles, so he decided to save money. However, we insisted on its replacement, after which the AT failure messages stopped! So, you need to look for the trouble in the vehicle as a whole, using an integrated approach, bearing in mind the possible interconnection and mutual dependence of all the units and systems of the vehicle.